PID (or “photoionization detector”. ) detection uses ultraviolet light to ionize VOC molecules in order to measure a resulting electric current. This simple method allows PIDs to detect VOCs at ultra-low levels, from parts per billion (ppb) to parts per million (ppm).

Most industry insiders know that volatile organic compounds (VOCs) evaporate rapidly when emitted into the air, react with other gases, and form other air pollutants. Exposure to them can result in serious health issues and in the long term, damage the local environment.

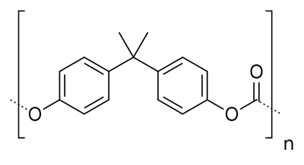

Additionally, the petrochemical industry produces and uses many VOCs, such as crude oil, gasoline, diesel, and plastics.

Like most other industrial gases and chemicals, VOCs can leak from pipes, tanks, valves and other critical equipment. This can result in immediate danger to life and at the very least, regulatory compliance issues for your organisation.

Advantages

The PID use of infrared spectroscopy and gas chromatography gives it a major advantage over other methods of VOC detection. PID detection is much faster, more sensitive, portable, and more versatile. It allows the detection of VOC at low levels in a variety of environments.

PID detection is used in the petrochemical industry to:

- Monitor worker exposure to VOCs and ensure compliance with occupational health and safety standards.

- Optimize the production process and reduce waste and emissions.

- Detect leaks, spills, or emissions of VOCs from all main equipment.

- Comply with local and international regulations and standards.

Limitations

Like anything else, PID detection does come with its limitations. Factors such as humidity, temperature, pressure, and interference from other gases can affect the accuracy of PID detection. Because of this, it is crucial that regular calibration and maintenance are performed to ensure reliability and precision.

When choosing a PID detector, it is important to consider the following factors:

- Range and resolution of the detector.

- Type and intensity of the UV lamp.

- Response time and recovery time of the detector.

- Battery life and power supply of the detector.

- Size and weight of the detector.

- Ease of use and display of the detector.

- Data logging and communication capabilities of the detector.

- Durability and resistance of the detector to harsh conditions.

- Cost and availability of the detector.

Conclusion

It’s fair to say that PID detection is a reliable and versatile method for monitoring VOCs in the petrochemical industry. By understanding both the benefits and limitations of PID detection, you can choose the correct equipment for your needs, ensuring the safety of your workers, the environment, and your business.

For further questions about PID detection or to learn more about our products and services, contact Rockall Safety at 02920 759 683. Our qualified team will be happy to help you find the right choice for your needs.