Environmental Applications for PIDs

Photoionisation Detectors (PIDs) are continuous, broad-spectrum monitors capable of detecting most volatile organic compounds (VOCs), ranging from simple compounds like methylene chloride (CH₂Cl₂) to complex ones, such as diesel fuel. For example, the MiniRAE 3000+ offers detection in the range of 0.1 to 15,000 ppm, while the ppbRAE 3000+ measures from below 1 ppb to 10,000 ppm. Fixed RAEGuard PIDs have a detection range of 0.01 to 100 ppm, 0.1 to 1000 ppm, or 1 to 1000 ppm. Environmental contractors and consultants frequently use these devices to monitor the remediation of industrial waste sites and decommissioned military bases.

Soil Remediation and Monitoring for Underground Storage Leaks

The UltraRAE 3000+ is ideal for detecting BTEX compounds (benzene, toluene, ethyl benzene, xylene) and Total Petroleum Hydrocarbons (TPH) found in gasoline, diesel, and jet fuel. This makes it an excellent tool for headspace analysis to identify soil contamination from leaking underground storage tanks. Environmental engineers and professionals in the petroleum industry can deploy this instrument to monitor contamination at gas stations, industrial sites, commercial transportation refuelling areas, and defence facilities.

Environmental Soil Contamination Monitoring

Environmental engineers and consultants often use the MiniRAE 3000+ for monitoring soil contamination at industrial real estate sites and former military bases. This device helps determine whether soil contains VOCs, providing critical information before the sale of land. Conducting due diligence and environmental impact assessments ensures that land can be safely rezoned for homes, shops, or parks.

Environmental Remediation Process Control

RAEGuard fixed photoionisation detectors are commonly used at remediation sites to monitor effluent levels and assess the efficiency of treatments such as soil vapor extraction, incineration, and bioremediation. The RAEGuard PIDs provide 4-20 mA outputs for continuous data recording and feature two dry contacts for process control if concentrations exceed alarm thresholds. The MiniRAE 3000+, which can run continuously and stores up to 15,000 datalogging points, can also be employed to monitor treatment effluent levels.

Headspace Screening

The MiniRAE 3000+ is highly effective for determining VOC levels in drinking water. Hydrologists and environmental engineers use it to monitor chlorinated solvents (e.g., carbon tetrachloride) and VOCs (e.g., toluene) in groundwater at drilling sites, closed industrial plants, military bases, and nuclear facilities.

Soil and Water Headspace Screening

Headspace analysis can help determine contamination levels in soil or water. Samples are collected in jars, which are partially filled and sealed with aluminum foil and a lid ring. After the contents reach room temperature, the MiniRAE 3000+ can be used to measure VOC concentration by inserting the probe through the foil to assess contamination levels.

Hazardous Waste Monitoring

For hazardous waste monitoring, the MiniRAE 3000+ assists contractors, engineers, and industrial hygienists in detecting toxic vapours and VOCs. This device is particularly useful for identifying hazardous areas at old disposal sites, disused industrial plants, and former military bases, as well as during the transport of hazardous waste. It also helps determine the appropriate personal protective equipment (PPE), such as Self-Contained Breathing Apparatus (SCBA), required for worker safety.

To see our range of RAE gas detectors, visit our product page, or give our team a call today for advice on 02920 759 638

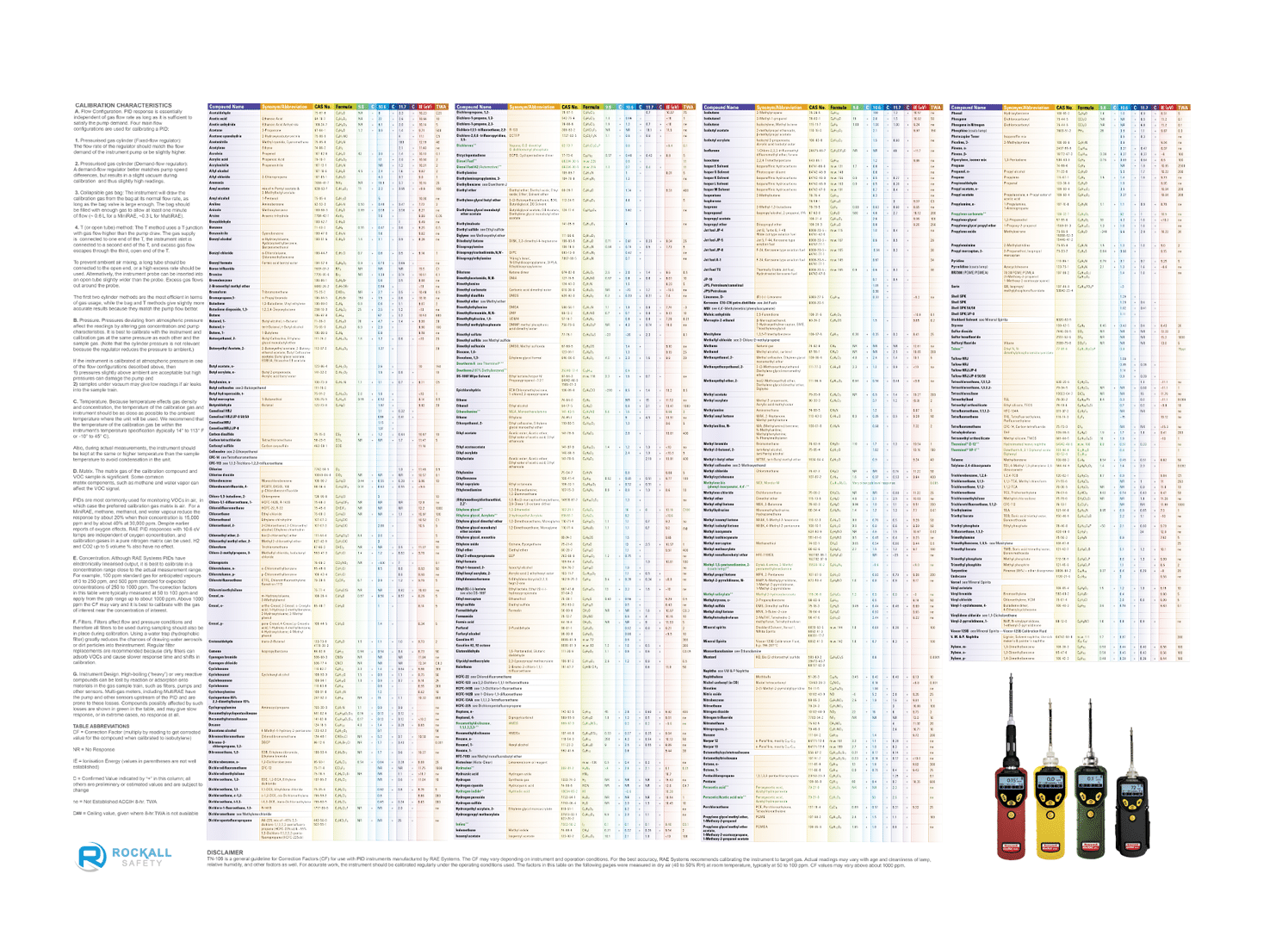

Honeywell PID Response Factor Chart – Download today!