What Is Bump Testing?

Bump testing is a critical safety procedure for ensuring the functionality of gas detection equipment. This guide will walk you through the essentials of bump testing, including what it is, why it matters, and how to perform it effectively.

A bump test is a quick test of a gas detector to ensure it is working correctly. This test involves exposing the device to a known concentration of the target gas to confirm that the gas sensors respond correctly, the alarms (visual, audible, and/or vibratory) are activated, and the readings on the device are accurate and within acceptable limits.

It is not a substitute for calibration but serves as a check that the detector will alert the user to dangerous gas levels.

Why Is Bump Testing Important?

Gas detection devices are life-saving tools in environments where toxic or flammable gases may be present. Regular bump testing ensures:

Operational Readiness: Verifies that the detector is functioning properly before use.

User Safety: Provides confidence that the device will warn of dangerous gas levels.

Regulatory Compliance: Many industries mandate regular bump testing to meet safety standards.

Skipping bump tests could result in undetected gas leaks, putting workers at risk of injury or death.

When Should You Perform a Bump Test?

Bump tests should be conducted:

Before Each Use: To confirm functionality for daily operations.

After Prolonged Storage: To ensure sensors and alarms are operational.

Following Exposure to Extreme Conditions: For instance, after dropping the device or exposing it to high temperatures or humidity.

Periodically During Use: Depending on manufacturer recommendations or workplace safety protocols.

How to Perform a Bump Test

Here’s a step-by-step guide to conducting a bump test:

Prepare the Equipment

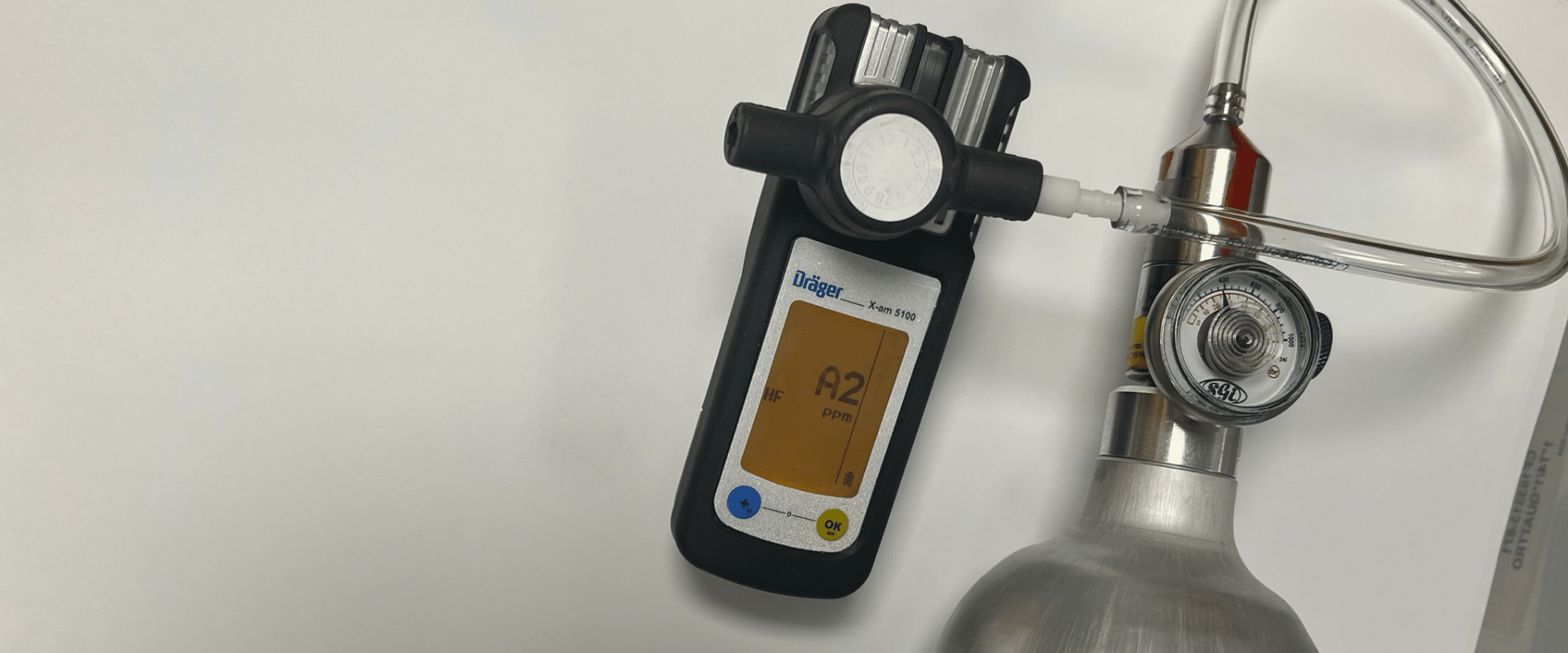

Connect the regulator and tubing from the gas bottle to the gas detector.

Expose the Detector to Test Gas

Apply the test gas to the detector for the time recommended by the manufacturer.

Observe the Device’s Response

Check if the detector’s sensors respond to the gas. Ensure the readings match the concentration of the test gas.

Take Corrective Action if Necessary

If the detector fails to respond, recalibrate it according to the manufacturer’s instructions.

Document the Test

Record the test results, including the date, time, and outcome, in a logbook or digital system for compliance purposes.

Best Practices for a Bump Test

Always follow the manufacturer’s instructions and recommended testing frequency. Use certified test gas with accurate concentrations. Train all personnel in proper bump testing procedures. Incorporate bump testing into your organisation’s safety program.

Bump Testing vs. Calibration

It is important to distinguish between a bump test and calibration:

Bump Testing

A quick functionality check, to ensure the detector responds to gas.

Calibration

A more comprehensive process that adjusts the detector’s sensors to ensure accurate readings.

While bump testing is conducted frequently, calibration is typically performed less often, based on the manufacturer’s guidelines.

Bump tests are an essential safety measure to ensure gas detectors function correctly and protect workers from hazardous gases. By incorporating regular bump tests into your safety protocols, you can enhance workplace safety, maintain compliance, and avoid potential accidents. Always prioritise proper training and adherence to manufacturer guidelines for optimal results.