Carbon Capture and Storage: Fighting Climate Change

Carbon Capture and Storage (CCS) is a key weapon in the battle against climate change. It helps cut greenhouse gas emissions by trapping CO2 from industrial sources and storing it safely underground.

How Carbon Capture and Storage (CCS) Works

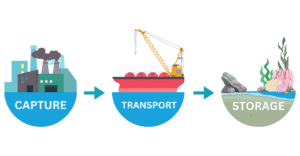

Carbon Capture and Storage (CCS) is a critical technology designed to reduce carbon dioxide (CO₂) emissions from industrial processes and power generation. It involves capturing CO₂ at its source, transporting it to a secure location, and permanently storing it underground. This process prevents CO₂ from being released into the atmosphere, helping to mitigate climate change.

CCS operates in three main stages: capture, transport, and storage. Each stage involves sophisticated engineering and infrastructure to ensure the effective and safe management of CO₂ emissions.

Capture

The first step in CCS is capturing CO₂ from industrial facilities, such as power plants, cement factories, steel mills, and chemical refineries. These industries generate large amounts of CO₂, which would otherwise be released into the atmosphere. Capture methods can be divided into three main categories:

-

Pre-Combustion Capture: This method involves removing CO₂ before the fuel is burned. Fuels such as coal or natural gas undergo gasification or reforming, producing a mixture of hydrogen and carbon dioxide. The CO₂ is then separated, and the hydrogen can be used as a clean energy source. This method is commonly applied in hydrogen production and integrated gasification combined cycle (IGCC) power plants.

-

Post-Combustion Capture: In this process, CO₂ is captured after fossil fuels have been burned. The exhaust gases from power plants or industrial facilities are treated using chemical solvents, membranes, or other separation techniques to extract the CO₂. This is the most widely applicable method, as it can be retrofitted to existing power plants.

Once captured, the CO₂ is compressed into a liquid-like state to facilitate efficient transportation.

Transport

After being captured and compressed, CO₂ must be transported to an appropriate storage site. The most common transportation methods include:

-

Pipelines: The majority of CO₂ is transported through pipelines, similar to those used for oil and natural gas. These pipelines are built to high safety standards to prevent leaks and ensure the CO₂ remains contained under high pressure. Pipeline transport is the most cost-effective method for large-scale CCS projects.

-

Ships: For regions without pipeline infrastructure, CO₂ can be transported by specially designed ships. This method is similar to transporting liquefied natural gas (LNG) and is useful for moving CO₂ across long distances, particularly from industrial sites to offshore storage locations.

-

Road and Rail Transport: In some cases, smaller quantities of CO₂ may be transported using pressurized tanks on trucks or trains. While this method is less common due to higher costs, it can be useful for pilot projects or locations without direct access to pipelines or shipping routes.

Once the CO₂ has been successfully transported to a designated storage site, it undergoes the final phase of the CCS process.

Storage

The final stage of CCS involves securely storing CO₂ in deep underground geological formations, preventing it from re-entering the atmosphere. These storage sites must have the right geological conditions to trap CO₂ safely for thousands of years. Common storage options include:

-

Depleted Oil and Gas Fields: Old oil and gas reservoirs are ideal for CO₂ storage because they have already demonstrated their ability to contain hydrocarbons for millions of years. Additionally, injecting CO₂ into these fields can sometimes enhance oil recovery, a process known as Enhanced Oil Recovery (EOR).

-

Saline Aquifers: These are deep rock formations filled with saltwater. They provide vast storage capacity for CO₂ and are widely available across the world. When injected into saline aquifers, CO₂ dissolves in water over time and reacts with minerals in the rock, forming stable carbonate compounds.

-

Basalt Formations: Some types of rock, such as basalt, can permanently convert CO₂ into solid minerals through a process called mineralization. This occurs when CO₂ reacts with minerals in the rock to form carbonate solids, effectively turning the gas into stone. This method is considered one of the most secure forms of long-term CO₂ storage.

Current Status and Future Potential

As of 2024, 29 CCS facilities operate worldwide, capturing nearly 40 million tonnes of CO2 annually. Moreover, as of September 2024, the UK has 67 commercial CCS projects in development.

The UK possesses a large CO2 storage capacity, with estimates suggesting over 70 billion tonnes of potential storage deep underneath the UK seabed.

The UK government recently pledged £22 billion over 25 years for two carbon capture clusters in Merseyside and Teesside. These projects aim to capture and store over 8.5 million tonnes of CO₂ annually, contributing massively to the UK’s net-zero emissions target by 2050. Furthermore, this funding is projected to create approximately 4000 jobs.

Meanwhile, the European Union has set a target to store 50 million tonnes of CO2 annually by 2030 through its Net-Zero Industry Act.

Why Carbon Capture Matters

As the world faces the urgent challenge of climate change, reducing carbon dioxide (CO₂) emissions has become a top priority. Carbon Capture and Storage (CCS) plays a big role in this effort by capturing CO₂ before it reaches the atmosphere, preventing its harmful impact on global temperatures. This technology is important for industries that produce high emissions, such as power generation, steel manufacturing, cement production, and chemical processing. By integrating CCS into these sectors, we can significantly cut emissions while maintaining industrial productivity and economic growth.

1. Reducing CO₂ Emissions from Major Sources

One of the most important reasons for implementing carbon capture is its ability to reduce emissions from key industrial and energy sectors. Many of the world’s largest CO₂ emitters, including coal-fired power plants, oil refineries, cement factories, and steel mills, are critical to modern economies but also produce vast amounts of greenhouse gases. CCS allows these industries to continue operating while significantly lowering their carbon footprint.

Without CCS, achieving deep emission reductions in sectors like cement and steel is extremely difficult, as these industries rely on chemical reactions that release CO₂ as a byproduct. CCS ensures that these unavoidable emissions are captured and safely stored instead of contributing to global warming.

2. Slowing Global Warming and Supporting Net-Zero Goals

Climate change is driven by excessive greenhouse gas emissions, primarily CO₂. Rising global temperatures have led to more frequent extreme weather events, rising sea levels, and disruptions to ecosystems. By capturing and storing CO₂, CCS helps slow these dangerous effects by directly reducing the amount of carbon in the atmosphere.

Many countries and organisations have set net-zero emission goals, aiming to balance the amount of greenhouse gases emitted with the amount removed from the atmosphere. CCS is a key component in achieving these goals, as it allows industries to drastically cut their emissions while renewable energy solutions continue to scale up. Without CCS, many industries would struggle to meet the ambitious targets set for 2050 and beyond.

3. Enabling the Cleaner Use of Fossil Fuels During the Energy Transition

While the world is moving toward renewable energy sources such as wind and solar, fossil fuels still play a significant role in global energy production. Many economies rely on coal, oil, and natural gas for electricity, transportation, and industrial operations. CCS offers a way to use these fossil fuels more responsibly by capturing CO₂ emissions at the source.

By making fossil fuel-based energy cleaner, CCS acts as a bridge technology during the transition to renewable energy. It ensures that existing power plants and industrial facilities can continue to function without causing excessive environmental harm. This approach helps balance energy security and sustainability, particularly in regions where renewable infrastructure is still developing.

Honeywell

BW Ultra

The Honeywell BW™ Ultra is an excellent option for monitoring multiple gases in confined spaces, with up to five sensors to detect various gas hazards. It easily covers the standard four gases needed for confined space monitoring—oxygen (O₂), hydrogen sulfide (H₂S), carbon monoxide (CO), and lower explosive limits (LEL). Plus, a fifth sensor slot offers flexibility to customise the device for specific needs, like adding a carbon dioxide (CO₂) sensor.

For more information, click here: BW Ultra 5 Gas Detector | O2, CO, LELs, VOCs & More | Rockall Safety

Sensepoint XCD

Drager

X-am 8000

The 1-to-7 gas detector can simultaneously detect toxic and flammable gases, vapours, and oxygen in either pump or diffusion mode. Its innovative signaling design and helpful assistant functions provide complete safety throughout the process. This detector can identify various gases, including LEL, IR LEL, CO₂, VOC (PID), O₂, CO, H₂S, NO, NO₂, SO₂, PH₃, HCN, Cl₂, and H₂, among others, with CO₂ detection as a key feature!

For more information, click here: Dräger X-am 8000 Multi-Gas Detector | Rockall Safety

PAC 8000

The Dräger Pac 8000 is a single-gas detector with sensors for gases like CO₂, Cl₂, HCN, NH₃, NO₂, PH₃, and OV.

Its large, non-verbal display shows gas concentrations clearly, along with units and battery life. Bright backlighting ensures easy reading, even in dark conditions.

For more information, click here: Dräger PAC 8000 Gas Detector | Single Gas Detector | Rockall Safety

Blackline Safety

Blackline G7

Blackline EXO 8

MSA

ALTAIR 5X

The MSA ALTAIR 5X monitors up to six gases simultaneously, offering versatility and durability in gas detection. It’s designed for reliability in challenging environments, making it ideal for industrial applications, including hazardous settings. The ALTAIR 5X supports a wide array of sensors, including O₂, CO₂, H₂S, CO, and VOCs. This flexibility suits applications where monitoring multiple gases is essential, covering extensive industrial safety needs.

For more information, click here: MSA ALTAIR® 5X Multigas Detector | Rockall Safety

Ultima X5000

The MSA Ultima X5000 is a high-performance, fixed gas monitor for hazardous gases in industrial settings. It offers advanced features for continuous, precise gas detection, ideal for carbon capture applications. The Ultima X5000 supports sensors for CO₂, H₂S, O₂, and other toxic or combustible gases. This capability ensures comprehensive monitoring in facilities where tracking multiple gases is essential.

For more information, click here: MSA ULTIMA X5000 Fixed Gas Detector | Rockall Safety

Crowcon

Crowcon Gasman (CO2)

Crowcon XGard Bright

The Crowcon Xgard Bright is a fixed gas detector with a flexible and intelligent design. It can detect various gases, including carbon dioxide (CO₂), flammable gases, and toxic gases. The detection capabilities depend on the installed sensor type. It offers robust monitoring with advanced features for carbon capture applications. Accurate gas detection is vital for both safety and efficiency. Many videos have been created about the Crowcon Xgard Bright, view here: Rockall Safety – YouTube