A guide to fixed gas detection

What is a Fixed Gas Detector?

Fixed gas detectors are stationary devices designed to continuously monitor the concentration of specific gases in a particular area. These detectors are typically installed in locations where there is a potential for gas leaks or emissions, such as industrial plants, laboratories, and underground parking garages.

The Difference Between Fixed and Portable Gas Detectors

While both fixed and portable gas detectors serve the same purpose of detecting gas leaks, they differ significantly in their application and functionality:

Portability: As the name suggests, portable gas detectors are designed to be easily moved from one location to another. They are often used for spot checks or in areas where gas leaks may occur intermittently.

Continuous Monitoring: Fixed gas detectors are permanently installed and provide continuous monitoring of gas levels in a specific area. They are ideal for locations where gas leaks pose a constant threat.

Alert Systems: Fixed detectors are often integrated with alarm systems or emergency shutdown procedures, providing a rapid response to gas leaks.

Data Logging: Many fixed detectors have built-in data logging capabilities, allowing for the tracking of gas levels over time and the identification of trends.

Key Features

Gas Specificity: Fixed detectors are designed to detect specific gases, such as carbon monoxide, methane, hydrogen sulphide, or oxygen.

Sensitivity: Detectors must be sensitive enough to detect gas leaks at concentrations that pose a risk to human health or safety.

Accuracy: The detector must provide accurate readings of gas concentrations to ensure reliable detection and response.

Reliability: Fixed detectors must be reliable and capable of operating continuously in harsh environments.

Alarm Functionality: Detectors should have clear and audible alarms to alert personnel of gas leaks.

Data Logging: The ability to record gas levels over time can be valuable for identifying trends and improving safety measures.

Maintenance: Fixed detectors require regular maintenance and calibration to ensure their accuracy and reliability.

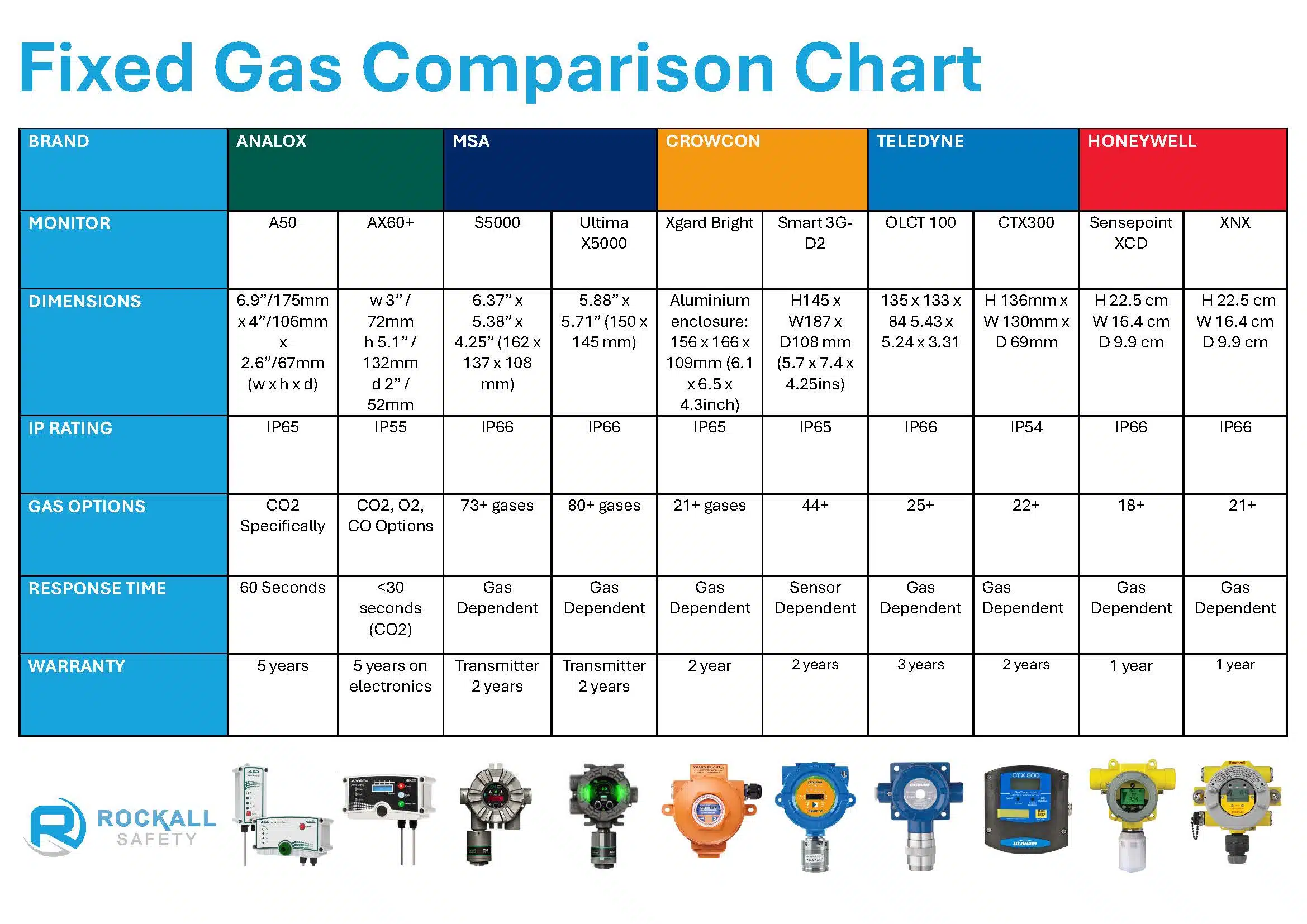

Fixed Gas Detector Comparison

See our comparison chart below, which features some of the top brands and products. Note; not every top product is listed, and you can see our full range of fixed detectors here

Rockall’s Turnkey Solution

Here at Rockall Safety, we offer a full turnkey solution, meaning that we will see your fixed gas installation through from start to finish, with ongoing support and servicing. This means that you get peace of mind knowing that your system installation is in good hands, and our expertly trained, CompEx certified, engineers, will be available to you at every point.

To read all about our Turnkey solution, click here

Analox A50 / AX60+

The A50 is a simpler, single-gas CO2 detector, while the AX60+ is a more versatile system that can measure multiple gases and offers more customisation options. The AX60+ is also suitable for larger installations and those requiring more advanced features.

A50

Designed primarily for CO2 detection.

Wall-mounted design.

Single-gas monitor.

4-20 mA output for CO2 only.

AX60+

Modular system capable of measuring CO2, O2, and CO.

Multiple sensor options for customisation.

Up to four sensors per setup.

4-20 mA or MODBUS output for each sensor.

Data output module for integration with business management systems.

Relays for ventilation or gas shut-off control.

MSA S5000 / Ultima X5000

S5000

Designed for demanding environments and harsh conditions

Operates in temperatures from -40°C to 75°C

Features a rugged enclosure and IP66/NEMA 4X rating for water and dust protection

Offers a wider range of sensor options, including infrared sensors for combustible gases

Can be operated by magnet interface, a single touch button, or via Bluetooth-enabled smartphone

Ultima X5000

Designed for ease of use and maintenance

Offers a longer calibration cycle of up to 24 months for certain gases

Features a user-friendly interface and tool-free sensor replacement

Provides remote monitoring and notification capabilities

Can be integrated with cloud-based monitoring systems

In summary, the S5000 is a more rugged and versatile system suitable for challenging environments, while the Ultima X5000 is designed for ease of use and maintenance and offers advanced features like remote monitoring and cloud integration. The choice between the two systems will depend on the specific needs of the application.

Crowcon Xgard Bright / Smart 3G-D2

Xgard Bright

The Crowcon Xgard Bright is a fixed gas detection system designed for demanding environments and harsh conditions. It operates in temperatures from -40°C to 75°C and features a rugged enclosure with an IP66/NEMA 4X rating for water and dust protection.

Key features of the Xgard Bright include:

- Wide range of sensor options

- Rugged construction

- Multiple operating modes

- Easy maintenance

- Remote monitoring

Smart 3G-D2

The Crowcon Smart 3G-D2 is a fixed gas detection system designed for ease of use and maintenance. It offers a longer calibration cycle of up to 24 months for certain gases and features a user-friendly interface and tool-free sensor replacement.

Key features of the Smart 3G-D2 include:

- Easy to use

- Long calibration cycles

- Tool-free sensor replacement

- Remote monitoring

- Cloud-based integration

Teledyne OLCT 100 / CTX300

OLCT 100

OLCT 100 Gas Detector Versions:

- OLCT 100 XP: This explosion-proof version is equipped with a choice of catalytic, MEMS, electrochemical, or semiconductor sensors, suitable for detecting combustible gases, toxic gases, or oxygen.

- OLCT 100 IS: This intrinsically safe version comes with an electrochemical sensor for accurate detection of toxic gases or oxygen.

- OLCT 100 XP IR: An explosion-proof model featuring an infrared sensor, designed for detecting gases such as CO2, CH4, and refrigerants.

- OLCT 100 XP HT: This high-temperature explosion-proof version is capable of detecting explosive gases at temperatures up to 200°C.

CTX300

Can detect oxygen, toxic and refrigerant gases, including carbon monoxide, hydrogen sulphide, methane, and ethylene oxide.

It has an improved sensor for CO2 detection, which can help to prevent the onset of hypercapnia, a condition that can lead to unconsciousness and death.

It is easy to use and maintain, with pre-calibrated sensors and an optional LCD display.

It is available with a wide range of sensor options, so it can be customized to meet the specific needs of any application.

Honeywell Sensepoint XCD / XNX

The Honeywell SensPoint XCD is a fixed gas detection system designed for a wide range of applications, including industrial, commercial, and residential settings. It offers a variety of sensor options to detect a range of gases, including carbon monoxide, oxygen, hydrogen sulfide, and methane.

Key features of the SensPoint XCD include:

Versatile sensor options

Easy installation and maintenance

Rugged construction

Remote monitoring capabilities

Compliance with industry standards

XNX

Designed for industrial and commercial applications.

Offers a wider range of sensor options, including infrared sensors for combustible gases.

Features a rugged construction and IP66/NEMA 4X rating for water and dust protection.

Can be operated by magnet interface, a single touch button, or via Bluetooth-enabled smartphone.

Meets or exceeds industry standards for gas detection.